Labels

HomeLabels

We manufacture all types of industrial and custom labels including automotive labels, machine labels, electrical panel labels, safety labels, barcode labels and product identification labels in Bangalore.

Precision-manufactured automotive dials with excellent colour matching, UV protection, and long-lasting performance.

View Automotive Dials

High-durability automotive decals designed to withstand harsh outdoor conditions, offering excellent adhesion and long service life.

View Automotive Decals

Custom roll form labels manufactured using premium materials, suitable for high-speed printing and automated application systems.

View Roll Form Labels

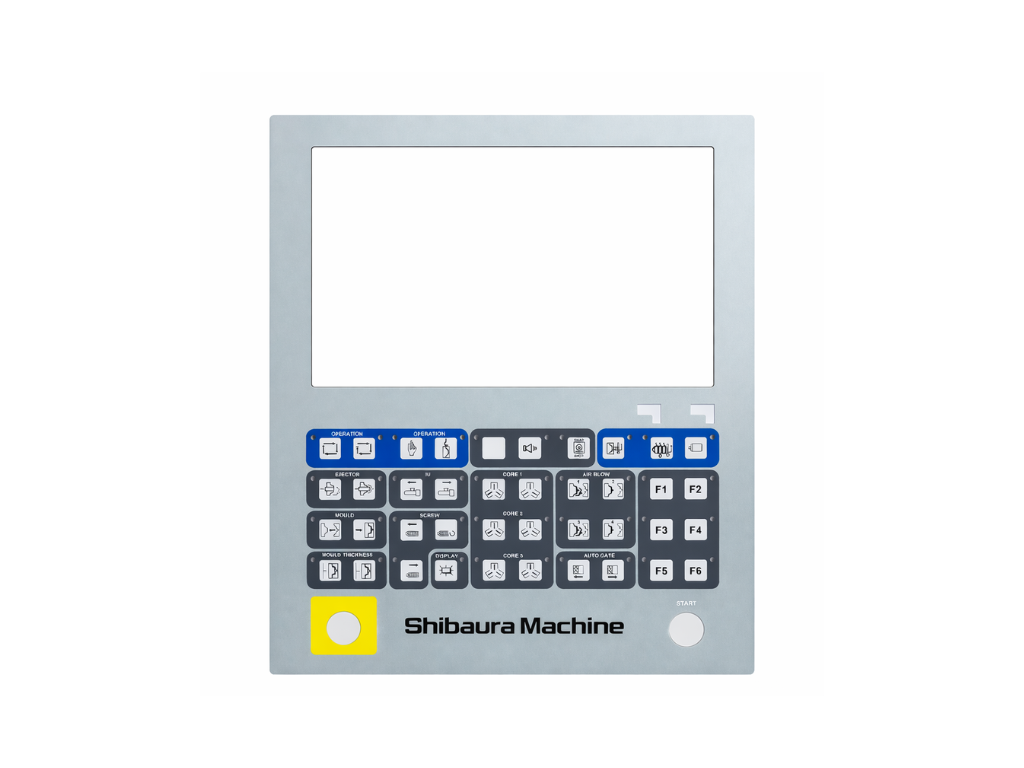

Durable graphic overlays designed for frequent use, offering clear visibility, tactile response, and long-term reliability.

View Keypad Graphic Overlays

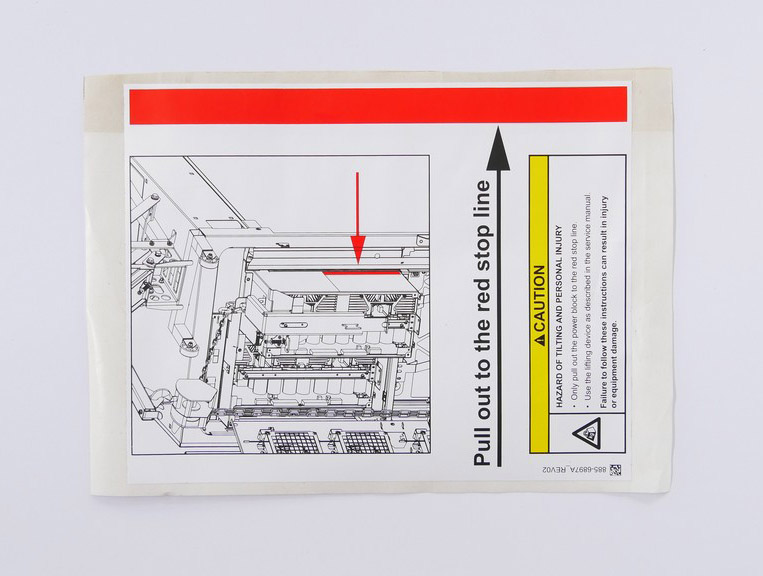

High-quality self-adhesive labels providing strong bonding, clear instructions, and enhanced product identification.

View Self Adhesive Labels

Robust metal nameplates built to perform in extreme environments, offering permanent identification and long-lasting durability.

View Metal Nameplates

Attractive PU dome labels that enhance brand visibility with scratch resistance and long-lasting glossy finishes.

View PU Dome Labels

Function-integrated membrane labels combining visual appeal and tactile performance for control panels and electronic equipment.

View Membrane LabelsSahara Labels is a premium label manufacturer in Bangalore specializing in industrial labels, custom printed labels, automotive labels, membrane labels, barcode labels and metal nameplates. We are one of the most trusted labels manufacturers in Bangalore serving electrical, electronics, automotive and OEM industries across India.

Our industrial labels are engineered to withstand heat, chemicals, moisture and harsh outdoor environments. As a reputed industrial label manufacturer in Bangalore, we supply durable labeling solutions for motors, transformers, control panels and machinery manufacturers.

We design and manufacture custom product labels, branding labels, safety labels and compliance labels as per customer requirements. Our custom labels are available in roll form, sheet form and die-cut formats.

As a leading label manufacturer in Bangalore, Sahara Labels manufactures a wide range of industrial and custom labels for multiple industries.

Our industrial labels are designed for extreme environments including heat, oil, chemicals and outdoor exposure. These labels are widely used in electrical panels, transformers, motors and heavy machinery.

We manufacture high-quality automotive labels such as dials, decals and warning labels that meet automotive durability standards and UV resistance requirements.

Our self adhesive labels offer strong bonding, long-lasting print quality and are suitable for branding, instructions and safety applications.

Sahara Labels is a trusted membrane label manufacturer in Bangalore supplying keypad graphic overlays for control panels and electronic equipment.

We manufacture aluminium and stainless steel metal nameplates for permanent product identification in industrial environments.

We manufacture industrial labels, automotive labels, membrane labels, self adhesive labels, PU dome labels and metal nameplates.

Yes, we design and manufacture custom labels based on material, size, adhesive type and application requirements.

Yes, we supply labels to OEMs and industries across India.

Sahara Labels is a trusted label manufacturing company in Bangalore with over 15 years of experience in supplying high-quality industrial and automotive labels. Our manufacturing facility located in Peenya, Bengaluru is equipped to handle bulk OEM requirements with consistent quality and timely delivery.

We follow strict quality control processes and supply labels to electrical, electronics, automotive, HVAC and engineering industries across Karnataka and India.